ALM Coffee Party IV – ChaRM Transport Risks – Missing Transport and the Transport History

The strict nanny

Do you remember this from your youth, when a far too strict supervisor saw the whole world as one big pile of risks and wanted to forbid you from going out? With the result that you no longer believed in a single risk?

The ChaRM has adopted this panicked attitude and risks falling into the same trap of false alarms. On the other hand: perhaps it is better to have one alarm too many than one too few?

Everyone has to define the right measure for themselves.

False alarm

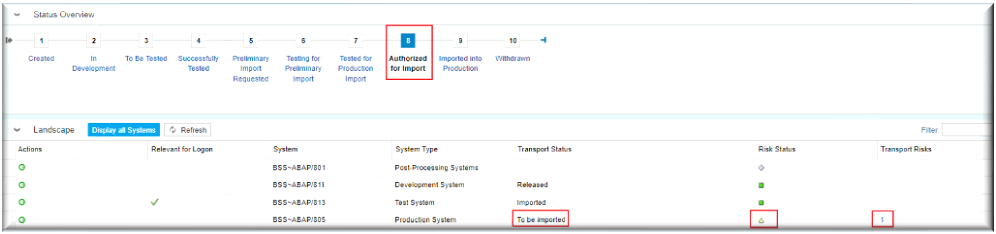

“Transport risks”: This column is available in the “Landscape” assignment block of a change document:

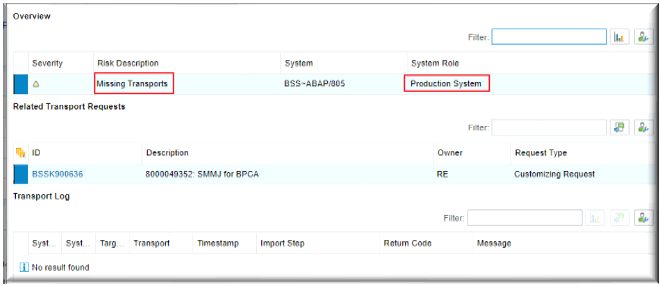

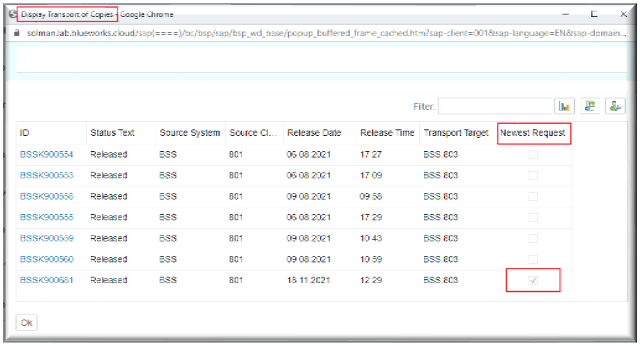

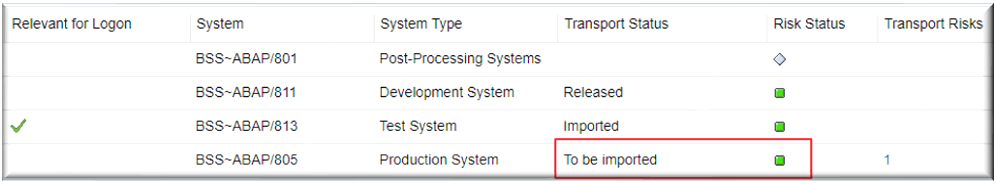

Wow! A yellow warning triangle! Look here! As conscientious change managers, we feel it is our duty to investigate the reported risk immediately. Looking closely with the magnifying glass, we discover that the “1” has the typical blue color for links, so we sharpen the mouse to hit this tiny jump point. And lo and behold! A pop-up will open:

I see. But now we are disappointed. It is clear that transportation is “missing”. After all, it is only waiting to be imported – its transport status says “To be Imported”. This banal fact is strongly reminiscent of the saying about the Maréchal de La Palice that if he were not already dead, he would still be alive.

But how exactly are these “missing” transports determined? As this functionality was originally built for Quality Gate Management, the SAP help on “Risks” is located there. Nevertheless, questions keep cropping up, so we would like to provide a more in-depth supplement here.

How does the number “Missing Transports” come about?

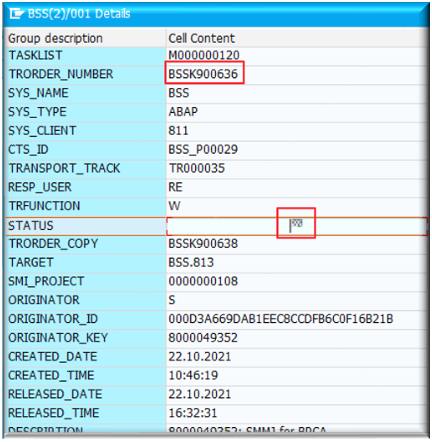

The ChaRM main administration table is /TMWFLOW/TRORD_N. First, all transports of a change document (or a cycle) that have the status “Released” are identified.

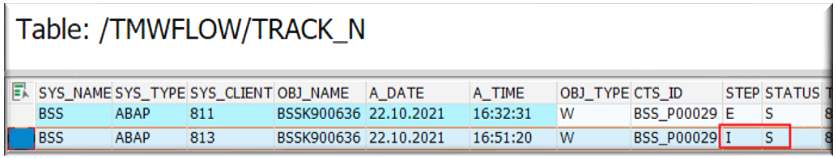

Now the ChaRM starts to check for each import system of a transport track in the second important table, the /TMWFLOW/TRACK_N, whether there are exactly as many entries with Step I as Import and one of the statuses S (Success), W(Warning) or R (Repaired) for the previously identified transports.

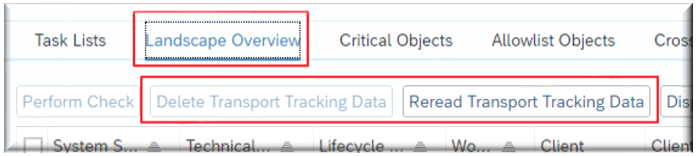

This table reflects the content of the transport history (TPALOG) of the managed system. If discrepancies have crept in between the ChaRM tracking table and the real transport history of the managed system, these two functions of the Change Admin Cockpit can be used to update the current status in the Solution Manager:

If transports are actually found that are not yet considered imported or repaired in this tracking table, a brief check is made to see whether they were imported in the previous system, if one exists.

If yes, then this transport is considered missing. However, if it is also missing in the predecessor system, it is ignored here because the transport is already specified as missing in the predecessor system.

Transports of copies (ToC) play a special role in normal changes (SMMJ) in a consolidation system (the first system that follows the source system, usually the QA system). This is because only the last, most recent ToC is correctly checked for successful import.

Incorrectly imported transports, i.e. those with a return code greater than or equal to 8, are also deleted from the set, as they receive their own entry under “Errors” (“Transport Error”), see section 2.1 below.

To ensure that this delicate mechanism also works after a system copy (system refresh), you must follow steps 2 a ii from note 2259615“ChaRM/QGM: Correct Procedure of Refreshing a System Managed by a SAP Solution Manager System“.

Educational cosmetics

We cannot change the calculation of “missing” transports, but we can decide which cases actually deserve a “yellow” warning triangle and which do not.

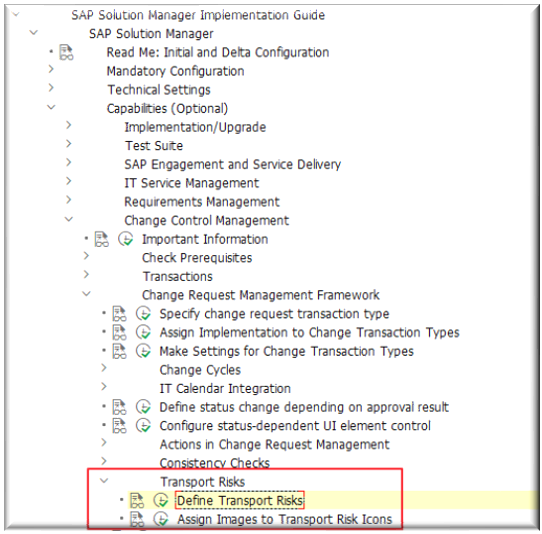

There is an option in Customizing to influence the display of the “risk status”.

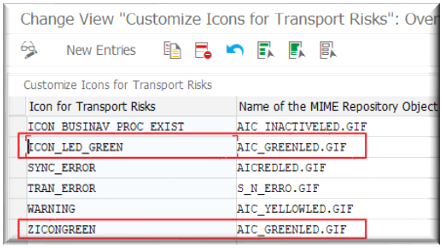

First we need to clone the default entry for the green led so that the key is no longer than ten characters:

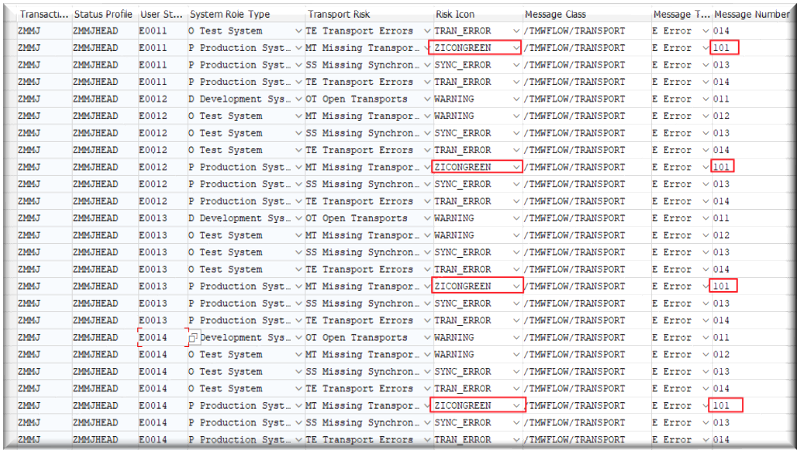

We then replace the warning with our new green led for all statuses where it is obvious that the import is missing, whereby we also replace the message /TMWFLOW/TRANSPORT 012 “Missing Transports” with the message 101 “To Be Imported”:

Figure 5 MT is green for all pre-import statuses

Do not panic

On the Titanic.

And then the display corresponds to reality:

The green LED tells us that we don’t need to worry about this line.

On the other hand, we know that if a yellow warning triangle does appear, we’d better take a look.

Further risks

Two risks, namely “Open Transports” in the development system and “Transport Error” in the import systems, are self-explanatory; the latter has already been mentioned above.

Synchronization Error

The “Synchronization Error” type is also interesting. It is a special case of a “missing transport” that can occur in landscapes that have more than one transport track, i.e. more than one source system with an associated productive system. For example, a landscape with an ERP track and a parallel second track with a master data or global trade system is popular.

It is created as follows.

First, the “missing transports” for both (we simplify) tracks are determined (again!) for the respective import systems. If the transports of the import system of one track have been fully imported but those of the parallel track have not, the transports of the defective track that have not been imported are counted and listed as “Synchronization error”.